It is T-SQL Tuesday time for February 2018, which is being hosted by Aaron Bertrand. One of the choices that Aaron offered was to write about something you are passionate about, outside of the SQL Server or tech community.

Making Beer at Home

About 18 months ago, encouraged by my friend Mike Witcher, I became somewhat serious about making beer at home. This was not my first foray into making beer, since I had made about four small two-gallon batches of beer with a Mr. Beer kit about fifteen years ago. Many home brewers get their first start on Mr. Beer kits, which let you make drinkable beer at a very low starting cost, as long as you can follow some basic directions and you pay attention to cleanliness and sanitation.

Mr. Beer Little Brown Keg

Using a Mr. Beer kit to make beer is kind of like making mac-n-cheese from a box. It is possible to make beer while having very little idea what you are actually doing. It is also very similar to using Microsoft Access as a database, which is something you might do as a beginner, that you don’t want to admit to later!

Fast-forward to 2016, and I was thinking about making larger batches of beer, using somewhat more serious equipment. I had met Mike when he bought my previous house in Parker, and we had become friends. He was a veteran home brewer, with many years of experience under his belt who urged me to give it a try.

I was already aware of The Brew Hut, which is the largest home brew supply store in Colorado. I made a couple of reconnaissance visits to the store, before I ended up buying a “Super Deluxe” brewing equipment kit very similar to this one.

Beginners Super Brewing Equipment Kit

A kit like this gives you just about everything you really need to make five-gallon extract batches of beer. This includes a couple of carboys, a four-gallon brew kettle, an immersion chiller, a thermometer, a hydrometer, and various other small accessories. This type of kit lets you do a partial boil, usually on a stovetop in your kitchen, which is often how brewers first really get started (after Mr. Beer). Many brewers successfully use kits like this for many years, with very good results. It is not necessary to spend a lot of money on equipment.

Of course, since I am a gadget nut, I could not resist immediately upgrading my brewing equipment, even before I brewed my first batch of extract beer! My first upgrades were a 10-gallon Anvil brew kettle, and an Anvil High Performance burner, with leg extensions. Anvil is the mid-level line of equipment from Blichmann Engineering, endorsed by John Palmer, who is the author of How to Brew. I also bought a 7.9 gallon FastFerment plastic conical fermenter.

Armed with this fancy new gear, I made a couple of Brewer’s Best extract batches (a Milk Stout and a Belgian Tripel), that seemed to turn out pretty well (at least to an uncritical audience of family and friends). Encouraged, I took an “Introduction to All-Grain Brewing” class, subscribed to several brewing magazines and bought a number of home brewing books. I also made the switch from using bottles to using five-gallon kegs to package my beer.

Then, I made a crazy, early jump to all-grain brewing on batch #3, brewing a pretty challenging Scottish Wee Heavy with a 26lb grain bill! Amazingly, this first all-grain batch turned out pretty well (even though it took me about six hours on brew day). I made one more extract batch (which was a gift from someone), but it has been all-grain ever since.

Equipment Fever

The equipment upgrade fever kicked into high gear during the autumn of 2016, which actually made my brewing days harder as I was learning the quirks of a new piece of equipment with nearly every new batch, while I was still very much a beginning brewer.

Batch #5 was a New England style IPA, using a new Ss Brewtech 7-gallon Chronical Brewmaster Edition stainless steel fermenter and a 10-gallon Infussion Mash Tun. This batch was all late hop additions and then dry hopping in the fermenter.

7-Gallon Chronical Fermenter 10-Gallon Infussion Mash Tun

Later that autumn, I built a wooden brewing cart that currently houses my three vessel brewing system. This includes a 15-gallon kettle that I use as a hot liquor tank (HLT), a 10-gallon mash tun (MT), and a 10-gallon Ss Brewtech Brewmaster Edition boil kettle that sits on a Blichmann HellFire burner. The boil kettle is set up so I can do a whirlpool for late hop additions and during wort cooling. I have two Blichmann RipTide pumps for moving strike and sparge water from the HLT to the MT, and for running the whirlpool.

Brewing Cart

Beer Samples

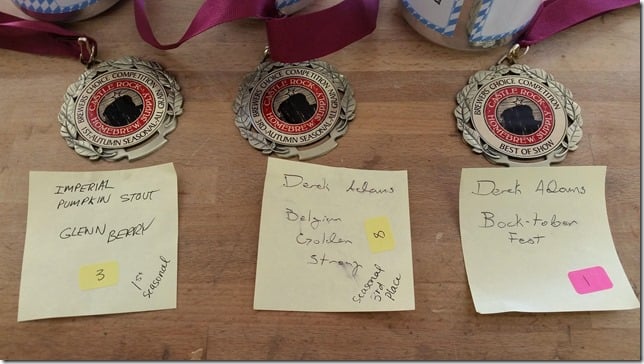

Since then, I have joined a local home brew club (The Parker Hop-Aholics), and I have been entering lots of local home brew competitions. I even managed to win a medal at a very small competition in Castle Rock. Entering competitions is a great way to get unbiased feedback and recommendations for improvement from certified beer judges. It also gives you more incentive to improve your brewing skills.

First Medal 14-gallon Fermenter in Action

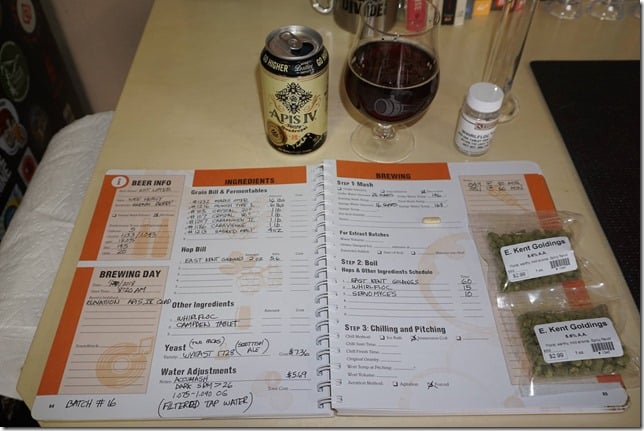

I have brewed 16, five-gallon batches of beer so far (which is almost 2.5 barrels). Every batch has the details recorded in a log book.

Brewing Log Book

Mash Tun Full of Grain

Even though this setup may seem pretty complicated, I am still just a beginner with a lot to learn. Brewing beer is similar to cooking or baking, where the basics are pretty easy, but becoming a master takes a lot more time and experience. The reason I enjoy brewing so much is because of how it makes me feel during and after the process. I love the smell of the grain during the mash, and how sweet it tastes as the starches are converted to sugars. The smell of the wort during the boil is also very nice.

The whole experience of a brew day is a lot of fun (and a lot of work). Going through all of the steps, trying to hit your numbers, as you listen to good music and drink some good beer is very enjoyable! Doing all of the required cleaning and sanitizing is not as much fun, but it is easier with a large sink and hot water out in my garage. After brew day, you get the chance to sample your beer as it is fermenting, and then finally get to taste the final product a week or two later.

February 19 Update:

I found out over the past weekend that I won medals in two different home brew competitions in Colorado. The first was a silver medal in the 13th Annual Peterson AFB Home Brew Competition for a 25C:Belgian Golden Strong Ale (in Table 16). The second was a gold medal in the Sweethearts Revenge 2018 for an Imperial Pumpkin Stout in the 30B: Autumn Seasonal Beer category.

13 thoughts on “T-SQL Tuesday #99: Home Brewing”

Awesome – I hope to get to your level someday. Planning on brewing an IPA this weekend.

Thanks for the kind words! My brewing level is not that high yet… Just having fun so far. Good luck on your IPA!

Blichmann is top of the line and too rich for my budget. I went the other route, started with 5 gal batches that took too long to consume, but gave away at 6 months in growlers. Switched to 2 gal batches which fit in 1.75 gal corney kegs. Forced carbonation over bottle conditioning saves soo much time! Just starting to brew “fruit” beers and as an adjunct, doing parallel “fruit” meads at the same time.

Switched from Chem Eng to SQL Developer 15 years ago as a result of selecting and implementing a LIMS for a Chem lab. The home brewing feeds the Eng in me. It also provides me with low IBU beer as I am the opposite of a Hop Head.

Good luck with your brewing. Love your set-up.

Some home brewers build/buy some very impressive equipment that is orders of magnitude more complicated and cool than my setup. I plan to eventually go to an all-electric HERMs system at some point. Maybe a Spike system like this: https://spikebrewing.com/collections/spike-systems

Well done, Glenn. I’ve been home brewing for a good number of years now and have to say your setup is impressive. I can sympathize with your Wee Heavy efforts. Most complicated recipe I’ve successfully completed was a dunkel weissen bock, which took ~15 lbs of grain, 1 month primary ferm, 6-weeks secondary and 3-months bottle conditioning before it was ready (using lager yeast and no refrig). But it was easily the best beer I ever made (~12% ATV). Planning and patience was what drew me to brewing initially but it’s the satisfaction of others with the result that I tend to enjoy the most.

Awesome work, Glenn! Congrats on the medals. You must be turning out some solid brews. I’m bringing my system out of retirement soon as I haven’t brewed in a couple of years. Looking to add a conical fermenter first. How do you like the SS fermenters? They look pretty sweet.

The Ss Brewtech Brewmaster Edition fermenters are really nice! Spike Brewing also makes some very good stainless conical fermenters.

If you bring some samples to SQLintersection at Orlando, I am in!

Nice work! I got bitten with the bug some decades ago and ended up going pro!

Well, from your e-mail address, it looks like you are working at a good place! Are you a brewer or doing something on the I.T. side?

I used to brew. We found out my son had celiac and I figured it wouldn’t be good to release untold amounts of gluten into the air (even if in the garage) :). I’m good giving it up. He’s totally worth it!

I will say, a couple great books that I referenced all the time were Brewing Classic Styles by Jamil Zainasheff and John Palmer not just for the recipes but for the styles themselves. I learned more about the styles from that book than any other resource. They also had/have a podcast you can download on the Brewing Network with the same name. I would also recommend the Yeast book by JZ and Chris White (of White Labs) and the Water book by John Palmer and Colin Kaminski. The last two are pretty deep but I loved the science behind it!

Happy brewing! (and ultimately, RDWHAHB)

Cheers,

Scott

Wow Glenn. Very inspirational! OK – this weekend the equipment is coming off the shelf, and my butt is getting outside to sit next to a nice steaming pot of wort.

I’ll stop in at Northern Brewer on Grand Ave here in St Paul and pick up stuff for a couple of 5-gal batches. Something light, something dark, little of this, little of that…

I used to brew a lot and loved it, so this was exactly the kick in the pants I needed! (nice distraction from servers…)

THANKS for this post. It’s always interesting to see what other geeks do for fun!

Good! Glad I could help motivate you to brew again! It is fun, and beer is good…